Champion: Iron Mountain – Western Europe

Business Sector: Information Storage and Management

UK Fleet Size:

Champion: Iron Mountain – Western Europe

Business Sector: Information Storage and Management

UK Fleet Size:HGV: 80

LCV: 370

Company Cars: Continental Europe only, 0 in UK

Grey Fleet: 200

Business overview

Herman Knaust founded Iron Mountain in 1951 in Livingston, New York. Knaust made his fortune by growing and marketing mushrooms. In 1936, he paid $9,000 for a depleted iron ore mine and 100 acres of land so that he could have more space to grow his product. But by 1950, the mushroom market had shifted, so Mr. Knaust decided upon a new business venture—one that would make good use of his mine, which he named “Iron Mountain”.

Today, Iron Mountain is the global leader in storage and information management services serving more than 220,000 customers in more than 50 countries on six continents. It is publicly traded on the New York Stock Exchange, is an S&P 500 company, and a member of the FORTUNE 1000 (currently ranked: 649). Iron Mountain has 24,000 employees in more than 1,400 locations worldwide, with revenues of nearly $4B.

It helps organisations around the world lower storage costs, comply with regulations, recover from disaster, and better use their information. The Centre for Brand Analysis (TCBA) annually ranks Iron Mountain as one of the UK’s top Business Super brands.

Leadership in fleet safety

To address work-related road safety, Iron Mountain UK has established a Fleet Safety Forum made up of transport specialists, risk managers, health and safety representatives, driver trainers, drivers and senior management.

Road safety is high on the agenda at Iron Mountain. Senior executives have supported the work-related road risk programme right from the start. The company has a Fleet Safety Policy which underpins all activity designed to reduce risk and promote road safety. It is complemented by a suite of global standards and policies.

Safety is at the top of the agenda within Iron Mountain with the area of transport being a key part. The teams across all our geographies continually focus on Drivers and Vehicles utilising the many processes and procedures put in place by the Fleet Safety Team. As an organisation we focus on continuous improvement across all aspects of our operations with safety a key area, we also adopt a very structured auditing process to ensure compliance.

John Ball

Vice President Operations Executive for Western Europe

The success of the risk management programme is driven by close collaboration between all key stakeholders. In addition to the operations team, who implement the assessment and training strategies, stakeholders include transport managers responsible for supporting initiatives at a local level, a risk management team to measure performance and keep senior managers informed of the initiatives.

Work-related road safety policies, procedures and activities

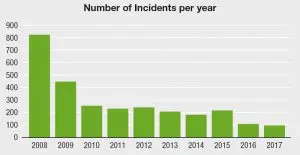

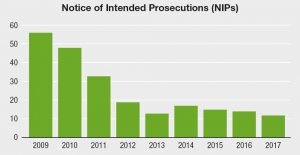

At the end of 2008 the company formulated a business case for a comprehensive programme of assessment and training. The case received leadership support and has ultimately led to a significant reduction in the number of incidents, claims and claims costs.

The key objective case was to improve the management of work-related road risks in order to:

- Reduce the risk of harm to employees and others

- Reduce the number of incidents

- Reduce costs

- Meet all legal requirements of health & safety legislation

- Meet the objectives of the corporate social responsibility plan

During 2008 Iron Mountain embarked on an in-depth fact-finding operation in partnership with Zurich Risk Engineering to understand what would be required to meet their aspirations for managing its work-related road risk

The partnership relationship developed as the project progressed from assessment through to risk reduction collaboration and, as a result of a series of gap analyses, we identified a number of necessary improvements.

This culminated in 2009 with the implementation of a comprehensive 5-point strategy and programme for managing our work-related road risk.

1: Driver Handbook Comprehension Check

2: Online Risk Assessment Programme

3: In House Driver Assessment and Training

While these assessments were, being rolled out across the business; five in-house driver trainers were recruited and trained. The role of the driver trainers is to ensure that practical in-vehicle assessments are carried out, any interventions based on the findings of the ‘ride along’, and the output from the online risk assessments and any post-incident analyses, are implemented quickly and effectively. The driver trainers focus on safety and environmental efficiency areas as well as other operational issues, ensuring that Iron Mountain employees drive as safely and effectively as they can. This approach applies to existing drivers as well as new recruits, where this team is fully involved in the recruitment and induction processes.

The number of dedicated driver trainers has reduced to two in recent times supplemented by a network of Transport ‘Sentinel coaches’ at local level.

4: Developing An On road Safety Culture

5: Driver Behaviour Telematics

A comprehensive roll-out plan ensured that everyone – drivers and their line managers – knew why the company was investing in this technology and what the benefits would be to them. Weekly calls with the telematics vendor ensure that managers understand the data that is generated and are in a position to do something with it – employees who meet the required driving-safety standards are rewarded and further help is provided to any drivers who fall short.

GreenRoad Elite status – Iron Mountain have in each of the years since it commenced, recorded the highest number of Elite drivers (pro-rata). In 2017, this was over 65% of its regular UK drivers, and are on course to increase this number in 2018.

Guidance for Drivers

Iron Mountain has invested considerable time and resource into its work-related road risk programme and collaborated closely with its partners to design and deliver bespoke solutions that not only mitigate risk but look to reduce it continually. None of this would work would have been possible without the trust and co-operation of the drivers.

Iron Mountain invests in its drivers. They all receive in-house Driver CPC courses and each driver is risk profiled against many areas of road safety, driving licence history, vehicle incident history, telemetry scores, Tachograph and road traffic violations. This is a combination of on-line and in-cab driving assessments undertaken by the dedicated in-house driver trainers.

The Driver Behaviour Telematics system gives drivers real time alerts in the cab via a small green yellow and red display so they can monitor their own driving. Incidents and violations are recorded and a driver report compiled via a web-based link for the manager to debrief with the driver.

Specific Examples of Procedures

Our team hold weekly conference calls to discuss and evaluate daily and weekly reports from our telematics supplier, our risk management team (vehicle incidents) and operational managers. There are numerous key performance indicators related to reducing risk, such as telematics scores and speed-by-speed zone. Personal objectives are tied into bonus schemes to reduce risk and the dedicated driver trainers are tasked with incident reduction within their regions.

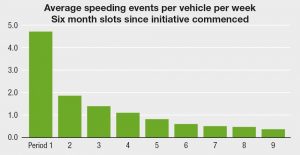

We introduced a ‘speed-by-speed zone’ daily report for all of our UK and Ireland vehicles, which reports any violation of more than 4 miles per hour above any posted limit. (For example 35 in a 30, 45 in a 40 etc.). We have worked with drivers to reduce the number of violations and within 6 months reduced it by over 80%. We now average less than one violation per week, per vehicle. This represents a remarkable achievement on the part of the drivers given that, collectively, they cover around 200,000 miles per week. The on-time delivery service KPI of 99.97% has not been affected by the initiative. Consequently, the drivers now realise that they don’t have to speed to get the job done and therefore feel more relaxed.

The Driver Behaviour Telematics System was deployed across the UK and Ireland fleets in 2011. It reports on various aspects of driving behaviour including; acceleration, braking, cornering, lane handling and speeding. Over 100 different vehicle movements are captured by the system. The driver sees real time alerts in the cab via a small green, yellow and red display. The objective is to remain in the green during the drive. Incidents or violations are recorded and a report for the driver provided via a web-based link for the manager to debrief with the driver. The scoring method is to aim to score below 20, which will suggest a ‘safer’ drive. 21-50 is Yellow and over 50 is red. We considered that <20 was too easy a target as our drivers had received one-to-one training and were very professional, so we created a target of <10. We have 99% of our drivers consistently achieving this target and we have seen considerable benefits from improved safety and reduced risk. Since 2015, we have reduced the target to a score of or below 5 to further optimise risk reduction and fuel efficiencies.

The system delivered a return on investment within eight months. It has now been installed across most of the European fleet, and is in 12 countries. The UK team assisted installation into Brazil in 2016 and we are looking to expand into five more Latin American operations. According to our telematics supplier, Iron Mountain records the best results worldwide.

We are accredited to the FTA Van Excellence scheme in the UK and Ireland and were the first company to be accredited a few years ago. Rory Morgan (Head of Logistics Support for Western Europe) attends the Van Excellence Governance Group and has done so since its conception. He has also stood as elected chair for the group for the three years.

The Central Compliance team works closely with our vehicle lease providers on the specifications of the fleet. They hold regular meetings and reviews with the post OEM body builders and invite drivers along to discuss the best options for vehicle safety and security with their fitters. Simple things such as where to position a grab handle can be very important to the driver.

Auditing and Review

In terms of competiveness; duty of care and risk reduction was the main drivers for the business. The investment and other initiatives were collated into business plans based on safety. The plan included close liaison and advice from our insurers and consisted of a project group to identify best opportunities by implementing best practice and exploring various initiatives. The plan was and is continually reviewed, with further opportunities then discussed and explored.

Iron Mountain’s customers often ask what the company’s performance in terms of road safety and sustainability. The Central Compliance Team is very pleased to demonstrate and share our successful approach. We are only too glad to assist other companies to work on their risk reduction and happy to share initiatives and ideas.

Performance Measures

Financial and Other Benefits

- Since 2008, vehicle incidents have been reduced by nearly 87%.

- Own damage and third party costs have been reduced by circa 78%.

- The reduction in incident rates have been reflected in Insurance premiums being reduced.

- On top of these cost reductions, we have seen significant fuel savings that represent circa 7% improvement on fuel efficiency as defensive driving directly correlates to fuel-efficient driving.

- We have also seen maintenance costs reduced by 4.5% in the first years’ initiatives and over 30% overall since the telemetry was installed, as the vehicles are driven more considerately.

There are other un-quantifiable cost savings through service and reputation. We have been awarded several road safety awards over the last few years, predominately for Driver and Road safety, and based on our initiatives and subsequent results.

Lessons Learned

The basics are relatively easy and not cost or resource prohibitive. Work on getting the fundamentals right first and see the benefits before increasing investment. If you do decide to invest in driver behaviour telemetry, do NOT consider it a ‘silver bullet’, you have to adjust based on the information delivered to manage and increase benefits. The system will not solve all ills on its own and employers have to learn to use and work with the data reported.

Managing work-related road risks is not a short-term fix, and has to be managed on an ongoing basis to ensure that any reductions in claims and collisions are sustainable, and so that further improvements can be made.

With Iron Mountain’s investment in in-house driver trainers, and a wide range of risk reduction strategies in place, including the proactive use of driver behaviour telematics, the business remains focused on the issue to ensure that the impressive reductions in incidents and claims continue.

The work-related road risk management programme that Iron Mountain have in place has been rightly recognised throughout the industry as being best in class. The ongoing improvements in the collision and claim rates are a testament to the excellent work that Rory and his team are doing on a daily basis – the results speak for themselves.

Andy Price

Practice Leader – Europe, Motor Fleet, at Zurich Risk Engineering

Iron Mountain has been a valued supporter of FTA’s Van Excellence scheme from the very start. Rory Morgan, Head of Logistics Support – Western Europe at Iron Mountain, was part of the original working group, which formulated the Van Excellence Code of Practice and was elected as Chairman of the scheme’s Governance Group for three years.

Throughout this process we have never failed to be impressed by the commitment, forward-thinking and attention to detail within Iron Mountain’s logistics function. The excellence of their operation along with a willingness to work with partners such as Zurich and to share their expertise within the van operational

Mark Cartwright

Head of Vans, Freight Transport Association

Other Information

Iron Mountain commits to new road safety initiative, Driver First Assist

Driver First Assist (DFA) have completed several one-day road safety-training courses for Iron Mountain as part of their Driver CPC programme.

The seven-hour course is a relatively new initiative designed to provide professional drivers with the necessary skills and training to deal with road traffic collisions (RTCs), in a bid to save more lives on the road. Nine Iron Mountain employees took part in the course, all of which work as driver trainers or compliance managers for the company’s transport operations.

Rory Morgan, Head of Logistics Support – Western Europe at Iron Mountain, who organised the initial course, first became interested in the DFA scheme after attending a presentation by Steve Rounds, star of Police Camera Action and qualified DFA trainer. “I was really impressed with the initiative and Steve’s explanation on how it can work effectively on our roads really brought the scheme to life for me. It was clear to me that Driver First Assist is an excellent idea and could really contribute to making our roads safer, so I was keen to host a course which our employees could attend,” explained Rory.

The course covers a number of simple skills that could mean the difference between life and death for accident victims in the first critical minutes after an RTC. From managing the scene and administrating basic first aid to reporting accurate information to the emergency services, the course provides the same vital, first-at-scene training that is given to trainee members of the police, ambulance and fire services.

“As a group of professional drivers, we all agreed that following the completion of the course we now feel much better prepared to respond if we were to come across an RTC. Most of us have done, or still do, spend many hours behind the wheel, so I felt it would be extremely beneficial for our trainers to be in a position where they could assist in case of emergency,” continued Rory. “This is a very worthwhile initiative. The course was delivered extremely well by the two trainers, who were engaging and enthusiastic. I would thoroughly recommend the course to anyone.”

David Higginbottom, founder of DFA said: “Rory and his team were very enthusiastic participants and we congratulate them all on becoming qualified DFA members. Our aim is to encourage more companies like Iron Mountain to support our imitative so that eventually we can have hundreds, if not thousands, of DFAs who are able to assist at an RTC and hopefully save even more lives on our roads.”