At Highways England, our ambition is that no one should be harmed while working or traveling on our network. To achieve this, we’re improving the safety of our roads through the way we design and build our schemes, how we maintain the network to a high standard, and how we manage traffic to keep our country connected. Our roads are among the safest in the world, but to reach our aim, we need to limit disruption and closures as much as possible.

When we look at where the most significant changes can be made to reduce incidents on our roads and improve safety, it’s clear that diesel spillages are something we should be focusing on. The effect on our network is significant in these incidents, as are the costs for commercial vehicle drivers and fleet operators.

When there is a diesel spillage on the Strategic Road Network (SRN) it has a financial, social, environmental and economic impact. The repercussions affect those directly involved, other drivers and the UK economy.

In 2018, Highways England recorded 314 diesel spillages involving HGVs, causing a range of events including journey time delays, risk to life and environmental issues. The cleaning up of diesel spillages is expensive and time consuming. Diesel exposure to the road surface for approximately 120 minutes has been shown to result in significant damage. This can cause further future disruption to the network with repair work to the carriageway and associated costs.

Many operators who’ve not had an involvement in diesel spillage incidents are not fully aware of the cost/damage and have not invested in the diesel spillage protection or equipped their vehicles to have spill kits on board.

The following are four real examples of the type of incident that occur on the SRN on a regular basis.

In November 2017 an articulated HGV was travelling northbound along the M11 when the driver swerved to avoid another vehicle, with the HGV ending up on its side. This caused the diesel tank to rupture and leak 500 litres of diesel onto the road surface. The emergency services were first to the scene and put a road block in place across 2 lanes of the motorway as the HGV had come to rest blocking the hard shoulder and lane 1.

In September 2017 an articulated HGV was travelling southbound along the M11 near to junction 12, when the HGV hit the central reservation demolishing both protective barriers on the southbound and the northbound carriageways. The impact resulted in a puncture to the HGV’s fuel tank leaking 400 litres of diesel onto the southbound carriageway. Contaminated soil in the central reservation also had to be replaced.

In September 2016 an articulated HGV was travelling westbound along the A14 near to junction 13. The driver lost control due to a burst tyre and was unable to stop the HGV before colliding with the central reservation. The vehicle overturned, rupturing the fuel tank and leading to a complete fuel system failure with the resulting diesel spillage stretching 200 metres along the carriageway and threatening nearby water ways.

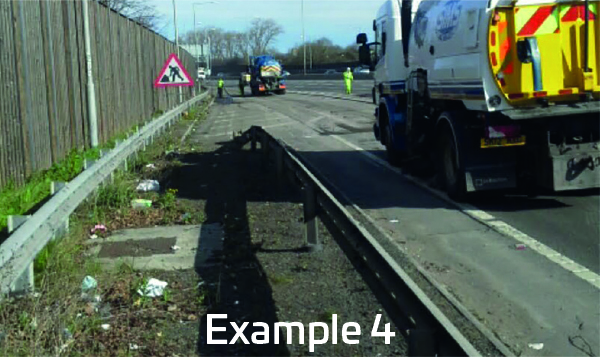

In April 2016 an articulated HGV was travelling northbound on the M1 when the driver swerved to avoid hitting another vehicle, resulting in the HGV jack-knifing across all lanes of the M1 northbound. A passenger vehicle travelling behind the HGV collided with the HGV’s fuel tank causing diesel to spill out across the carriageway. There was also some fuel leakage from the passenger vehicle that was wedged under the HGV.

Cost Recovery

In all these examples, the operator’s insurer was pursued to recover the cost of repairs.

Diesel Spillage Best Practice Guide

To assist commercial vehicle drivers and operators in preventing diesel spillages Highways England are looking to implement a series of interventions to reduce the frequency and severity of incidents associated with diesel spillages from commercial vehicle drivers on the SRN.

Highways England has developed a best practice diesel spillage prevention guide for commercial vehicle drivers and operators which will include, why spillages occur, steps taken to prevent spillages and the procedure to follow in the event of a spillage. To complement this, a cost document has been developed to raise awareness of the financial impacts of diesel spillages on the SRN. Highways England will also review best practices for fuel tanks’ protection and sizes and publish the results via a best practice note where necessary.

The best practice guide and cost document are aimed at commercial vehicle drivers and operators and seeks to improve awareness around the impacts of diesel spillages as well as improve understanding on the actions to take in the event of a diesel spillage.

The overall aim is to reduce the frequency and severity of diesel spillages on the SRN.